Basic Compressed Air Filter Information

Filters are one of the most important components in a compressed air system.

Clean, dry, oil free compressed air and gas is a basic need for many industries.

One drop of unwanted oil can cause an entire automated process to malfunction.

It can cause seals in pneumatic valves and cylinders to swell, resulting in sluggish operation -

or in worst cases, complete seizure of moving parts.

3 things that can contaminate your compressed air system and ruin your product or processes:

1) Solid particles come from ambient air contaminants like dust and from rusted, oxidized pipework.

They will cause pneumatic equipment to malfunction, cause instrument and control failures, and contaminate end products.

2) Condensed water droplets come from the humidity in ambient air.

Water will oxidize pipework and pneumatic equipment, ruin paint finishes and end products.

3) Liquid oil and oil vapors are introduced by compressor lubricants and by hydrocarbon

vapors present in ambient air. Oil-free compressed air is particularly important in food and pharmaceutical processes.

While a dirty system can usually function adequately, it does so at the expense of downstream components.

Liquid water and contaminants can damage the inside of pipes and other pneumatic components.

Also, many pneumatic valves and cylinders contain small orifices that can easily get plugged with contamination.

Because compressed air quality requirements vary considerably by industries, so does the type of filter needed.

Matching the level of filter used in the system to the quality of air required is the most cost effective

and energy efficient option.

Sizing compressed air filters at 2 x (twice) the compressors cfm flow rate will

lower the pressure drop in the filters.

This will result in:

1. Saving energy

2. The elements will last 2 x longer

3. Save on maintenance expense

Basic Filter Tips:

- Install piping by-pass for maintenance of filters.

- For critical applications install duplex filter system with piped by-pass.

- Install differential gauge to monitor element life.

- Change when DP is 10 psig or gauge is in the hi-yellow or red zone.

- Use auto drain as contaminants collect on the bottom of the filter housing and must be drain away to prevent re-entrained.

- Keep spare filter element kits on hand to prevent down time.

- Check drains and DP gauges for proper operations daily.

Compressed Air General Purpose Filters ( Particulate )

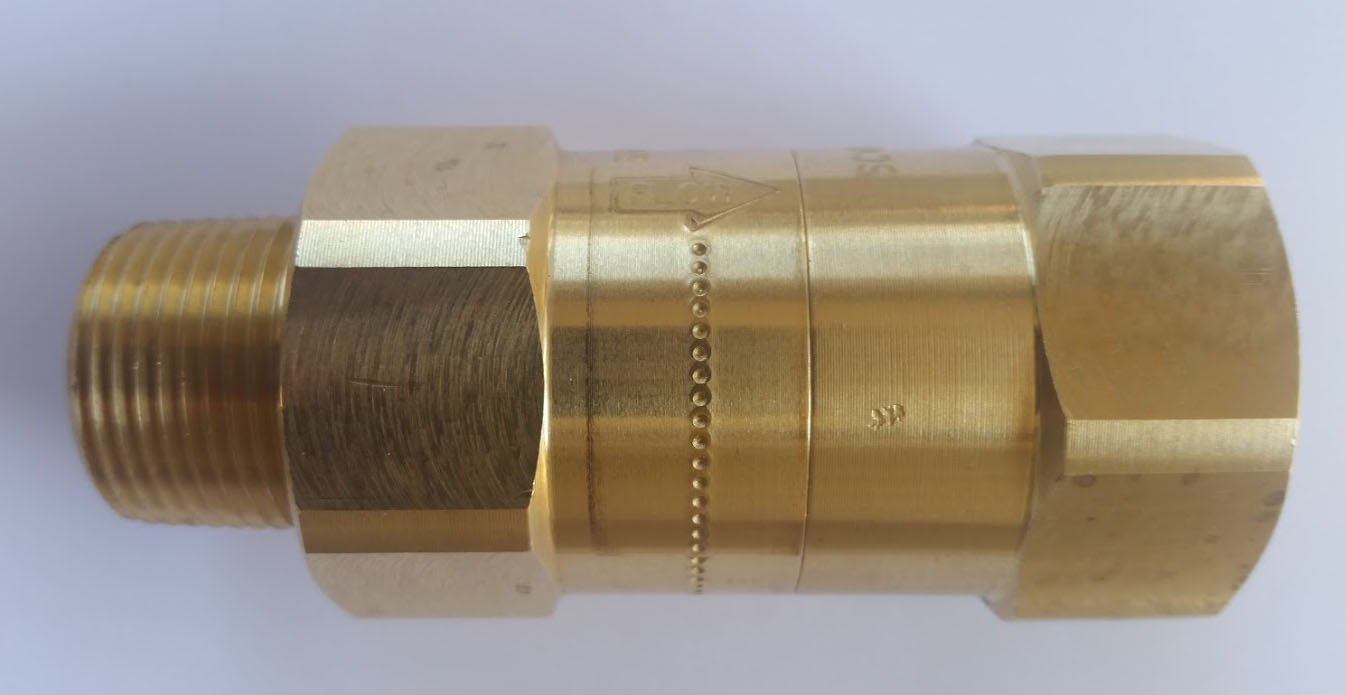

General Purpose Filter / Particulate Filter

Oil Removal Filter / Coalescing Filter

- Removes harmful oil aerosols by coalescing action.

Coalescing by definition, means " To come together".

It is a continuous process by which small aerosols come in contact with the fibers in the filter media,

uniting with the collected aerosols and growing to emerge as a droplet on the downstream surface of the media

which by its weight is gravitationally drained away.

Air flows enters from inside to outside through the filter media in oil removal filters / coalescing filters.

Microns rating 0.03 through 0.01 microns. Watch the arrow on filter for flow direction.

Contaminants collect on the bottom of the filter element and liquid must be drain away to prevent re-entrained.

There are manual drains, float drains, timed solenoid drains & electronic level drains all do a good job in the right application.

ISO 8573.1 Air Quality Classes range from class 1 through 6.

The maximum oil content remaining in parts per million by weigth (class 1 = 0.008 ppm) up to (class 5 = 21ppm)

that will pass through the filter element .

Remember the lower the part per million number, the more contaminants removed &

the higher the air pressure drop through filter.

Typically, oil removal filters / coalescing filters are installed downstream of general purpose / particulate filters for oil aerosol removal,

and to insure high efficiency and long element life when an adsorber / vapor removal filter is installed.

- Oil Removal Filter / Coalescing Filter are used in oil free compressed air applications as the second filter.

Compressed Air Line Adsorber Filters

Adsorber Filter / Vapor Removal Filter:

- Removes oil vapors, oily odors and solids particulate specifically for those applications

that will not tolerate the presence of oil vapors and associated odors.

The core consists of multi wrapped layers of impregnated activated charcoal particles to increase its

purification qualities.

Air flows enters from inside to outside through the filter media in adsorber filters. Microns rating 0.01.

Oil concentration of 0.003 parts per million by weight. Watch the arrow on filter for flow direction.

Contaminants collect on the bottom of the filter housing and must be drain away to prevent re-entrained.

There are manual drains, float drains, timed solenoid drains & electronic level drains all do a good job in the right application.

ISO 8573.1 Air Quality Classes range from class 1 through 6. The maximum oil content remaining in parts per million by weigth

(class 1 = 0.008 ppm) up to (class 5 = 21ppm) that will pass through the filter element.

Remember the lower the part per million number, the more contaminants removed & the higher the air pressure drop through filter.

Typically, adsorber filters are installed downstream of general purpose filter / particulate filters and oil removal filter / coalescing filters

- for oil aerosol and odor removal.

- Adsorber Filter / Vapor Removal Filter are used in true oil free compressed air applications as the third filter.

Who establishes quality industry standards for filters?

ISO 8573.1 was developed in 1992 by ISO (International Organization for Standardization) to help plant engineers specify

desired compressed air quality globally by providing “Quality Classes” for solid particulates, humidity and oil. Quality classes provide engineers with an internationally accepted unit of measure.

A typical pharmaceutical plant, for example, would have a compressed air specification of ISO Quality Classes 1.2.1.

This is equivalent to 0.1 micron particulate filtration, -40°F (-40°C) dew point, and 0.008 ppm (0.01 mg/m3) oil filtration.

No matter what language is spoken and what unit of measure is used, using ISO 8573.1 Air Quality Classes ensures that your factory

will get the compressed air quality you specified.

|

ISO 8573.1 Quality Classes

|

|

Quality

Classes

|

Solid

Contaminants(maximum particle size in microns)

|

Maximum

Pressure

Dew Points

°F (°C)

|

Maximum Oil Content(droplets, aerosols,

and vapor ppm w/w (mg/m3)

|

|

1

|

0.1

|

--94 (-70)

|

0.008 (0,01)

|

|

2

|

1

|

-40 (-40

|

0.08 (0,1)

|

|

3

|

5

|

-4 (-20)

|

0.8 (1)

|

|

4

|

15

|

38 (3

|

4 (5)

|

|

5

|

40

|

45 (7)

|

21 (25)

|

|

6

|

-

|

50 (10)

|

-

|